|

planetsoarer supercharged V8 - part III |

by Peter Scott

Part I

Part II

Estimating Boost and Eaton pulley change

Supercharger Kit

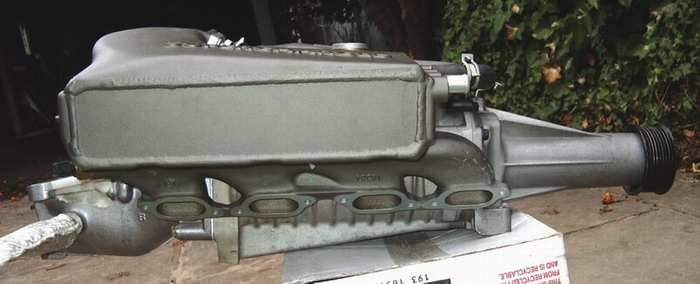

The Supercharger bits have arrived from England. I got a M112 Eaton supercharger complete with twin water/air intercoolers and most importantly, the water circulation pump.

The blower and intercoolers - looks a treat doesn't it? Nice and new looking. It is from a

2001 XKR Jaguar with 8000 miles on the clock - very fresh and new. This cost 350 pounds -

I thought that was a bargain.

Something I was pleasantly suprised to get as well was the throttle body adaptor with twin

bypass. I thought I would have to make one of these up - this will save a lot of work.

Air goes in the back, comes out the top of the supercharger and is split into the two

intercoolers. Water takes away the heat and the cool air then comes out of these four

oultets into the V8.

It's in such good condition - I was very pleased.

Here I have already hacked off one of the brackets on the supercharger - it fouled the

starter motor in the valley of the V8.

This is the stock flange before I hacked it off - It hits the starter motor. Because I

wont to lower the blower to fit under the bonnet - this flange had to go.

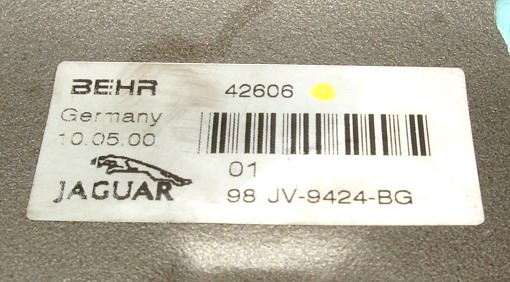

Looks like the intercoolers are made by BEHR in Germany. Looking inside the intercoolers

the quality looks to be very high.

This is what I really wanted - the genuine Jaguar V8 water pump for the intercoolers.

Comes with a proper mounting bracket to stop vibrations - and it's designed for the job

and will have the correct flow rate and will last and last without making lots of noise.

This cost 90 pounds. Total cost was $1300 to my door in Australia, then 2 weeks later I

got a tax bill for $300 - so $1600 for these bits.

This is the intake manifold from motor#2 (I have 2 in the shed). Somehow I have to get

that big throttle onto my supercharger, find a spot for the cold start fuel squirter (snap

bang in the middle here) and find a spot for the idle air control valve (not pictured here

- but the hole at the front is where it normally bolts too.)

I crudely hacked off the bottom half of the intake manifold and mounted the injectors to

start a dummy fit. Somehow the remaining manifold ports have to be welded up to the

intercoolers.

The starter motor wasn't such a big deal in the end, the throttle intake clears it leaving

enough room to shut the bonnet.

This is the dummy fit. I used balls of aluminium foil which were squashed between the

engine and the bonnet to measure how much room I had to play with. Then I made a simple

template that sits on the valve covers so I know how much room I had. Currently in this

photo the supercharger fits under the bonnet. However the front and rear water bridge

needs massive modification.

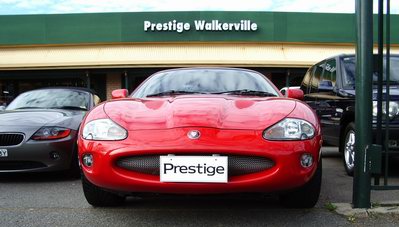

Down the road from where I live look what they have!

$120 000 of secondhand Jag.

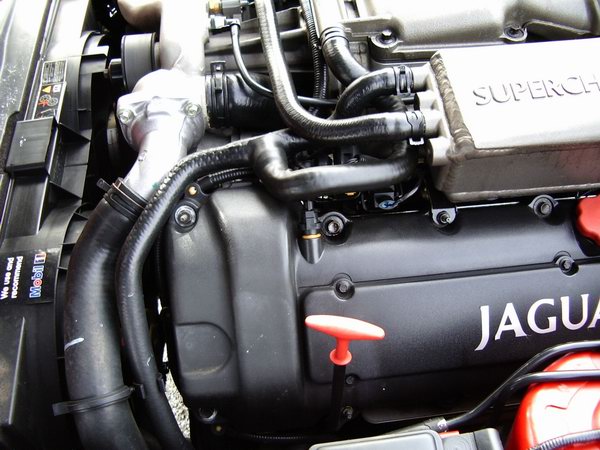

And yes on the bonnet.......

Very convenient to have a sticky beak - see where the hoses go, how it all works and where

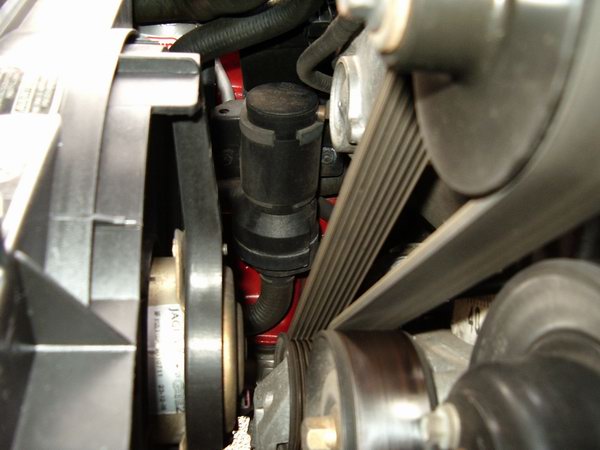

the water pump is mounted. This is the cool water in pipe before it splits to both

intercoolers.

More coolant hoses - I wanted to see which way the coolant ran - these pipes are the hot

water out.

The water pump tucked up real tight. The bottom of the pump "sucks" in the hot

water and it is pump out the side to the front mount heat exchanger (sort of like an

intercooler - but fillled with water). This coolant system is independent of the engine

cooling system. Lots of tight bends in the intercooler system - I'm tempted to find

out how much the genuine hoses cost - tight bends with rubber hoses is a pain. The

original hoses were'nt available when I got my supercharger. Top right is the supercharger

pulley - see the snout? - my replacement pulley will sit flush with the end of the shaft.

The stock pulley is also 8 ribs and look how the belt wraps so far around the pulley -

maximum contact for no slip. Running the same blower with my 6 rib pulley may cause

slippage - I will have to pay attention to getting the maximum wrap possible to avoid

slippage - running a gator back belt might help too.

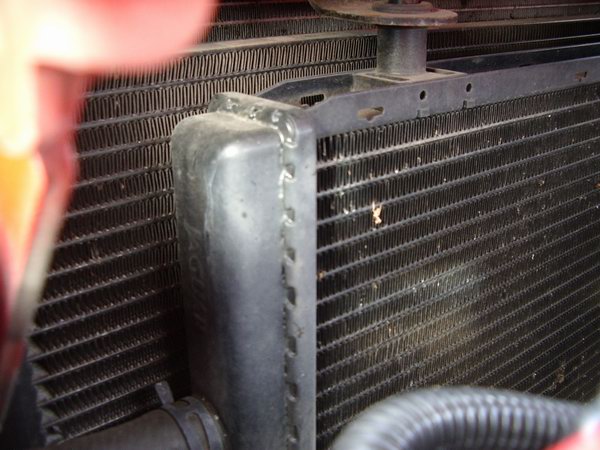

The stock Jag heat exchanger - always seems to be the first point of an upgrade. Just like

a front mount intercooler for a turbo car - this is the part of the car that limits power.

I'll pull the bumper off the the Soarer and see how big I can go. Might be able to pick up

a second hand radiator that will fit?

The rear water brigde will also have to be chopped up to allow the throttle to sit nice

and low - I'll get the throttle inlet to sit just above the starter motor. The water will

have to be re-routed up and behind the throttle somehow.

The blower can't sit on top of the front water bridge to have any chance of getting under

the bonnet. Massive cutting and shutting will have to happen here as well. The water

thermostat and the front coil are also in the way.

THERE'S A LOT TO DO!

Getting a Supercharger Kit is a great idea!