|

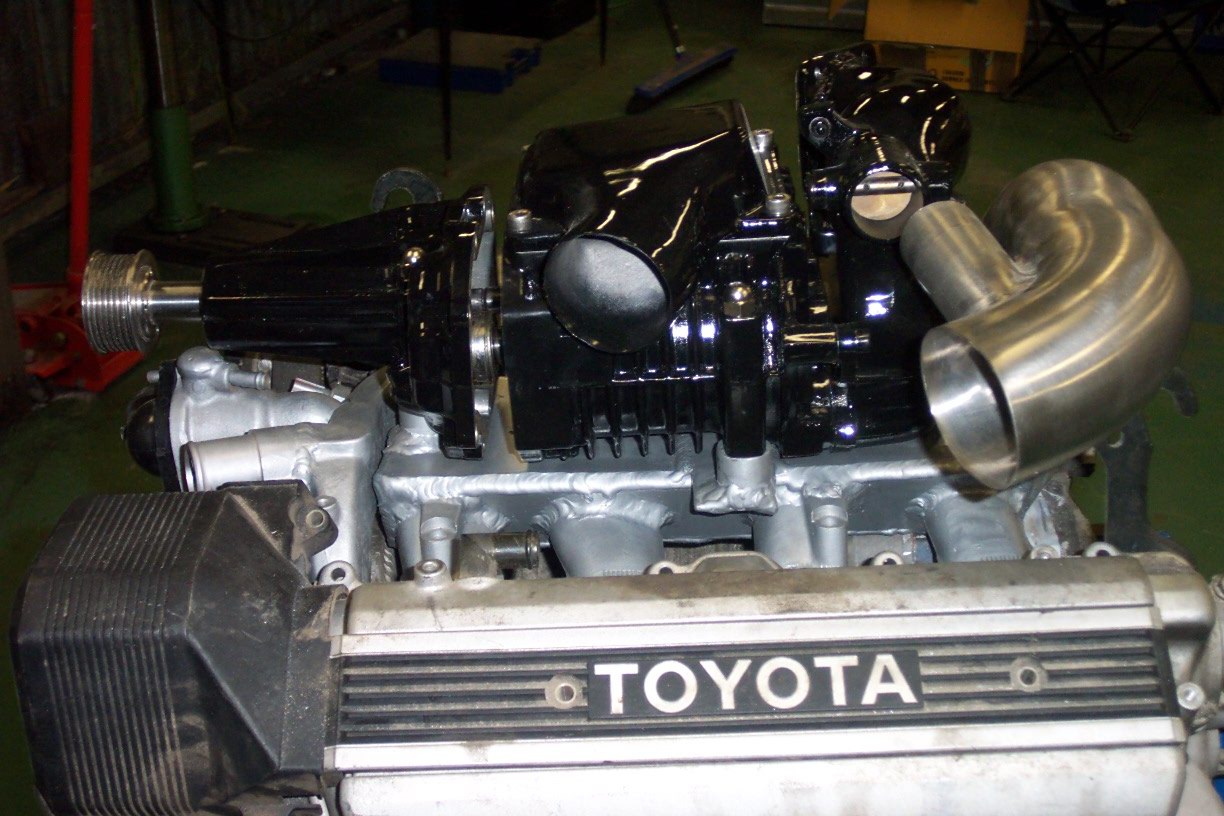

Joel Alexander's Supercharged 1UZ-FE V8 |

|

by Peter Scott

May 2004

Back in May 2004 Joel Alexander fabricated a manifold to suit an Eaton m90 . He milled the ports close to the flange to get a flat surface to weld the aluminium plates to and pressed out some bell mouths to weld into the plates.

He tig welded the ports (better control), and mig welded the top and bottom plates (cooler

with less distortion). The cast ports welded very easily - cast filler wire was used.

The hole for supercharger was dictated by the pulley position of the supercharger lining

up with the existing serpentine belt on the engine.

His V8 was for a ski boat - so the bell housing had to be shortened for the marine

gearbox.

The bottom plate of the manifold had to have a curved bottom to clear the starter

motor. Two days and $160 later he was all done!

The bypass valve came with the supercharger while Joel made the housing to suit. From the

top of the oil filler cap to the top of the supercharger is about 90mm.

Joel's been welding for 15 years.

June 2004

Meanwhile my Jaguar supercharger arrived from England.

The blower cost 350 pounds with intercoolers. Supplied by http://www.jagweb.com/justjags/

When I purchased it Just Jags still had one left so I posted on Lextreme.com that someone else should get the same blower. Joel knew straight away that for his ski boat that water intercoolers would work perfectly - so sure enough.........

July 2004

Joel bought the other twin intercooled jag supercharger from England. Joel can use endless cool river water to remover heat from the supercharger - a far superior case to a road car! Joel sold his existing M90 supercharger setup.

Joel planned to cut of the ports and bottom plate of the intercoolers to adapt new ports

for the 1UZ-FE.

Joel milled new manifolds out of a billet piece of aluminium flat and formed aluminium tube to fit up into the intercoolers. He used Rochester fuel injectors (450cc) and made custom fuel rails.

October 2005

This photo show the dummy assembly, there will be a lot more fabrication to finish the job.

Check out the boat the engine going into!!!! yeah Baby!!

The install is about half done here. Still to come are the throttle body adapter and bypass valve. The rear water bridge is not yet done and the throttle body not yet fitted.

February 2005

After a bucket load more of fabrication and ECU tuning the motor now goes real hard at 10 psi boost.

![]()

![]()

![]()

![]()

![]()

The intake air doesn't get above 35 degrees with a continuous supply of cool fresh river water.

The 6 rib belt hasn't slipped yet - the pulley is 65mm. Joel also fabricated the exhaust himself. Joel has had plenty of hot Chev motors before but nothing pulls as hard as this motor. The supercharged 1UZ-FE engine is especially sweet sounding at 5500 rpm. His favourite thing is taking mates for a ride in the boat and watching their jaw-drooping surprise when he nails the throttle and the boat leaps from the water.

The motor is unopened and runs the stock compression ration of 10:1. With proper tuning and charge cooling detonation hasn't been a problem.

Joel has also been fabricating a Ford Thunderbird M90 intercooled setup for Gary Nimmo's Soarer. It will fit under the bonnet and will run a small intercooler. The Thunderbird set up takes air from the right hand side into the back of the charger, blows it out the top into an intercooler and back into the rear of the manifold. Typically Ford M90 chargers are around the $200 on ebay.

Join the discussion on this project on Lextreme.com

If you are logged in as a member then click here: